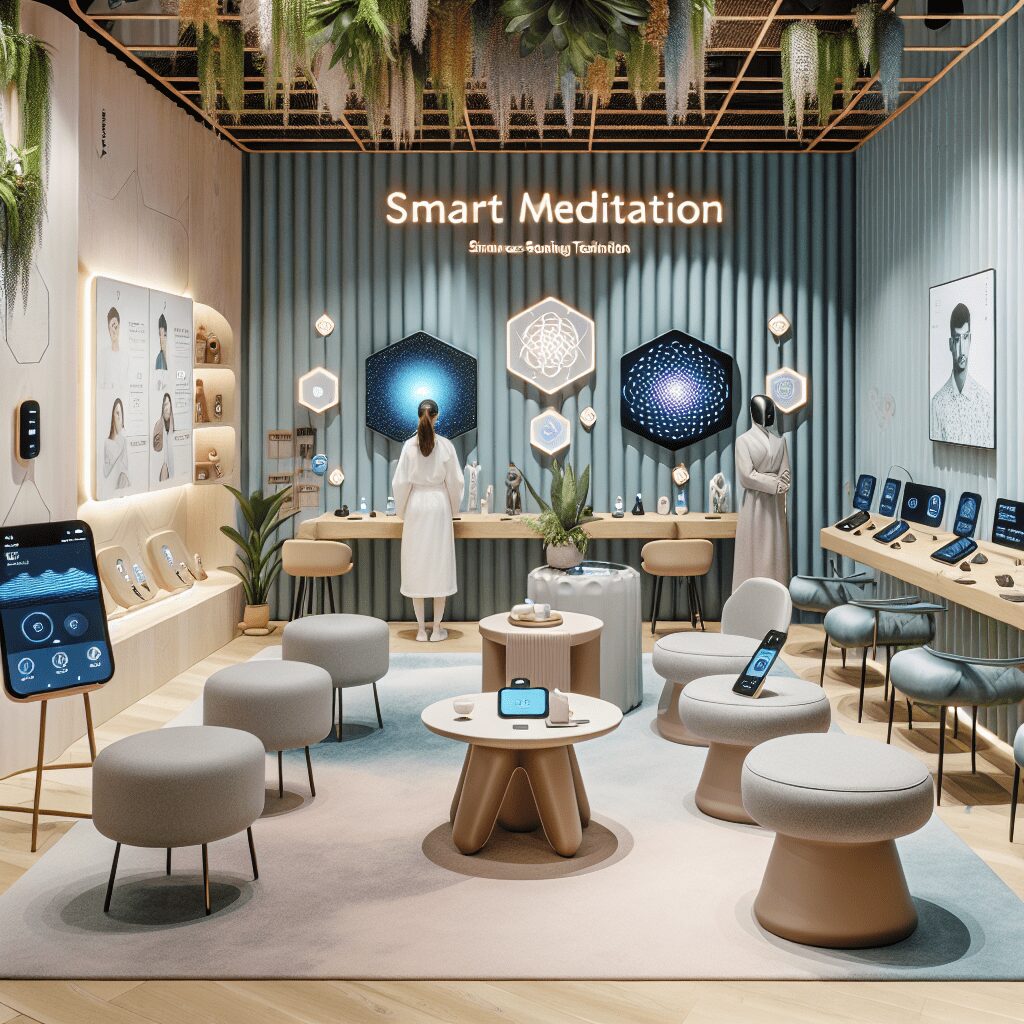

Prioritize your mental well-being daily. Enhance your life by nurturing your mental health with the Smart Meditation app. Break free from stress, alleviate anxiety, and enhance your sleep quality starting today.

How To Reduce Residual Stress In Welding?

Tackling the Heat: A Guide to Minimizing Residual Stress in Welding

Welding, the backbone of countless manufacturing processes, melds materials into a single entity using high heat. However, this fusion dance often leaves behind an unwanted guest – residual stress. This stress, if not addressed, can lead to distortion, cracking, and diminished structural integrity. So, how can we unhitch this unwelcome hitchhiker? Let’s delve into the art of minimizing residual stress in welding, ensuring your projects stand the test of time and stress.

The Fundamentals of Fending Off Residual Stress

-

Preheating to Perfection: Picture this; you’re about to embark on a welding journey. Preheating might seem like an extra step, but it’s akin to warming up before a sprint. It slowly introduces heat, reducing the temperature difference between the welding arc and the material. This gentle introduction minimizes the thermal shock and, subsequently, the residual stress. It’s like telling the metal, “Hey, we’re about to run a marathon. Let’s warm-up.”

-

Post-Weld Heat Treatment (PWHT) – The Stress Reliever: Ever felt the need to unwind after a stressful day? Metals aren’t so different. After welding, treating the material to a bit of heat therapy can work wonders. This controlled heating and cooling cycle relaxes the weld and surrounding areas, significantly reducing stress. Think of it as the metal’s spa day, essential for its well-being.

-

Taking It Slow and Steady With Controlled Cooling: Throwing a heated piece into the cold abyss might seem like a quick fix, but it’s a recipe for disaster. Controlled cooling allows the weld area and the surrounding material to gradually return to room temperature, avoiding the creation of tension zones. It’s the tortoise’s approach in the age-old fable—slow and steady wins the race.

-

Stitching It Up With Intermittent Welding: Instead of going full throttle with continuous welding, consider intermittent welding – a series of short welds with spaces in between. It’s like stitching fabric, where each stitch reinforces without overwhelming. This technique not only conserves material but also allows each section to cool incrementally, reducing overall heat input and, in turn, residual stress.

-

Choosing the Right Filler Material: Just like picking the right partner for a tandem bike ride, choosing a filler material that harmonizes with the base metal can make all the difference. A mismatch can lead to excessive stress due to differing rates of thermal expansion and contraction. Compatibility is key, ensuring a smooth ride with minimal stress.

Strategies for Avoiding Welding Woes

-

Employing Low-Stress Welding Techniques: Techniques like TIG (Tungsten Inert Gas) welding offer greater control over heat input than more intense methods such as stick welding. This fine-tuned heat management reduces the potential for residual stress.

-

The Magic of Weld Sequencing: Similar to choreographing a dance, the order in which welds are performed can influence the final outcome. Strategic weld sequencing distributes stress evenly and minimizes distortion. It’s about making the right moves at the right times.

-

Adopting a Design for Welding Approach: Sometimes, the best solution is prevention. Design modifications, such as the inclusion of relief cuts, can preemptively address areas prone to high stress. It’s about designing with foresight, anticipating stresses before they arise.

In the grand scheme of things, welding is as much an art as it is a science. By understanding and implementing strategies to reduce residual stress, we not only enhance the structural integrity of our welds but also extend the lifespan of the final product. So, the next time you’re gearing up for a welding project, remember, a stitch in time saves nine. With a bit of preparation and the right techniques, reducing residual stress is well within your grasp, ensuring your welded creations are both strong and stress-free.